RAPID + TCT 2024 is now open, hosting over 400 exhibitors at the Los Angeles Convention Center for the next three days.

Returning to the West Coast for the first time in nearly a decade, North America’s largest 3D printing trade show offers a chance to see the latest innovations from the industry’s major players.

The 3D Printing Industry team will bring you the inside scoop on all the news from RAPID + TCT 2024.

To kick things off, we took a morning run through the show floor to provide our first look at the must-see technology that visitors shouldn’t miss in LA.

New 3D printers at RAPID + TCT 2024

A brief scan of the show floor unveils a slew of introductions to the industrial and consumer 3D printer markets.

3D Systems has added to its family of EXT Titan Pellet systems. The new EXT 800 Titan Pellet 3D printer was unveiled for the first time today. It combines high-speed extrusion and a large 800 x 600 x 800 mm build volume into a smaller footprint.

3D Systems’ newest offering is compact enough to fit through a standard set of double doors, potentially increasing the accessibility of its Titan Pellet technology to more manufacturers with smaller workspaces. It is also said to enable 10x faster 3D print speeds and 10x lower material costs than comparable filament systems.

Another key player in the large-format polymer space is BigRep. The German-based company has launched the VIIO 250, its brand-new industrial FDM 3D printer for large-scale, engineering-grade parts. The company is calling this its most automated and intuitive 3D printer, optimized for 24-hour production.

BigRep is also showcasing the ALTRA 280, which it announced last month. This will be the 3D printer’s first appearance in North America. Interestingly, the ALTRA 280 features four DSX extruders, two of which can be operated simultaneously. The company claims this dual extrusion functionality is reliable, productive, and capable of producing functional parts with complex geometries.

Fans of large-format additive manufacturing may also wish to visit the Thermwood Corporation booth, where there are several very large 3D printed parts. These include molds and tools for aerospace applications produced using the company’s proprietary Large Scale Additive Manufacturing (LSAM) technology.

Netherlands-based 3D printer manufacturer Additive Industries has revealed its newest powder bed fusion (PBF) 3D printer, the MetalFab 300 Flex, on day one of RAPID + TCT 2024.

The company is marketing its new offering as the “only metal 3D printer with a flexible build area.” Customers with a monthly or lifetime license will be able to extend the build area from 11.81 x 11.81 x 15.75in to 16.54 x 16.54 x 15.75in at any time. Additive Industries’ CEO, Mark Massey, claims this is especially useful for manufacturers wanting to produce both small and large parts without incurring the upfront costs of a larger 3D printer.

Stratasys is winning the battle for RAPID + TCT floor space with a huge booth that immediately greets visitors at the show’s main entrance. Today at 2:30 pm, the company will reveal the latest addition to its medical portfolio, the J5 Digital Anatomy 3D printer. This new system is designed to meet the growing demand for affordable, high-fidelity, realistic anatomical models.

The Stratasys Truck, a mobile showcase of the firm’s other 3D printers and solutions, is also parked at booth #1501.

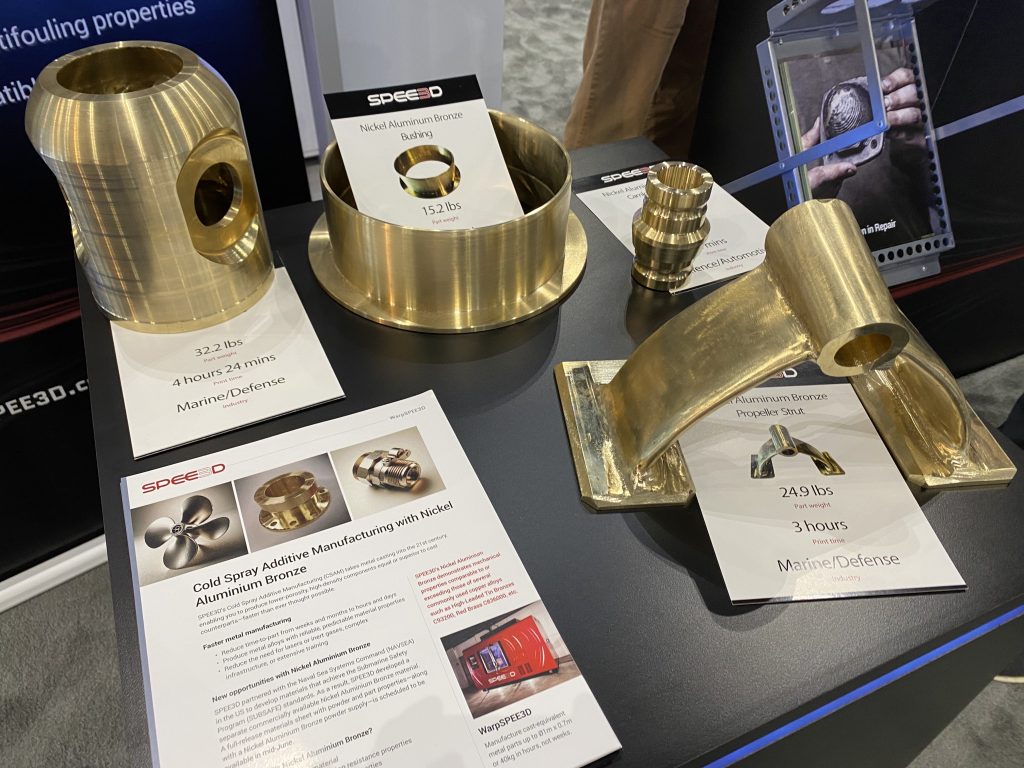

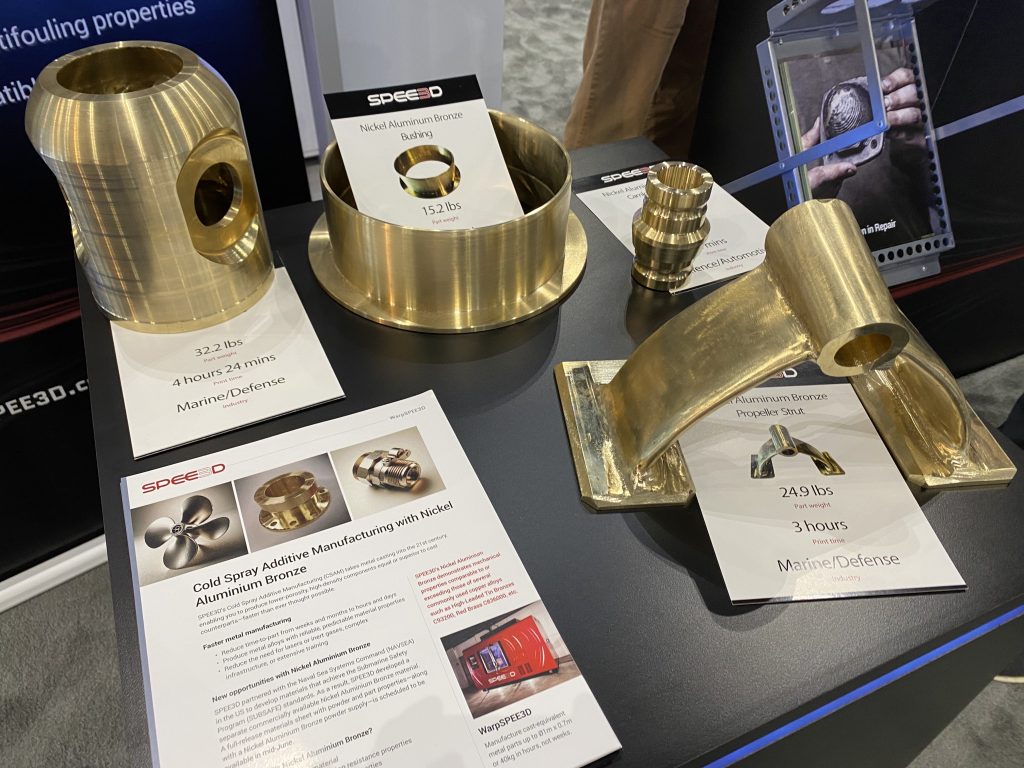

Earlier this month, SPEE3D launched TitanSPEE3D, the newest addition to its large-format cold-spray 3D printer portfolio. The 2.4m diameter x 1m tall system is not present at this year’s show. However, the company does have some fully-dense, large-scale metal parts produced by the TitanSPEE3D.

Throughout the week, SPEE3D will also be 3D printing parts using its new Nickel Aluminum Bronze material which it developed in partnership with the US Naval Sea Systems Command (NAVSEA).

Until last week, US-based metal 3D printer manufacturer Additec’s name was not on the RAPID + TCT 2024 exhibitor list. The company’s last-minute decision to attend the show was driven by growing interest in its metal 3D printing technology. CEO Brian Mathews told me that so many customers have expressed interest in seeing Additec in LA that they simply had to attend.

The company has an Apple Vision Pro headset at its booth, which visitors can use to interact with Additec 3D printers in virtual reality (VR).

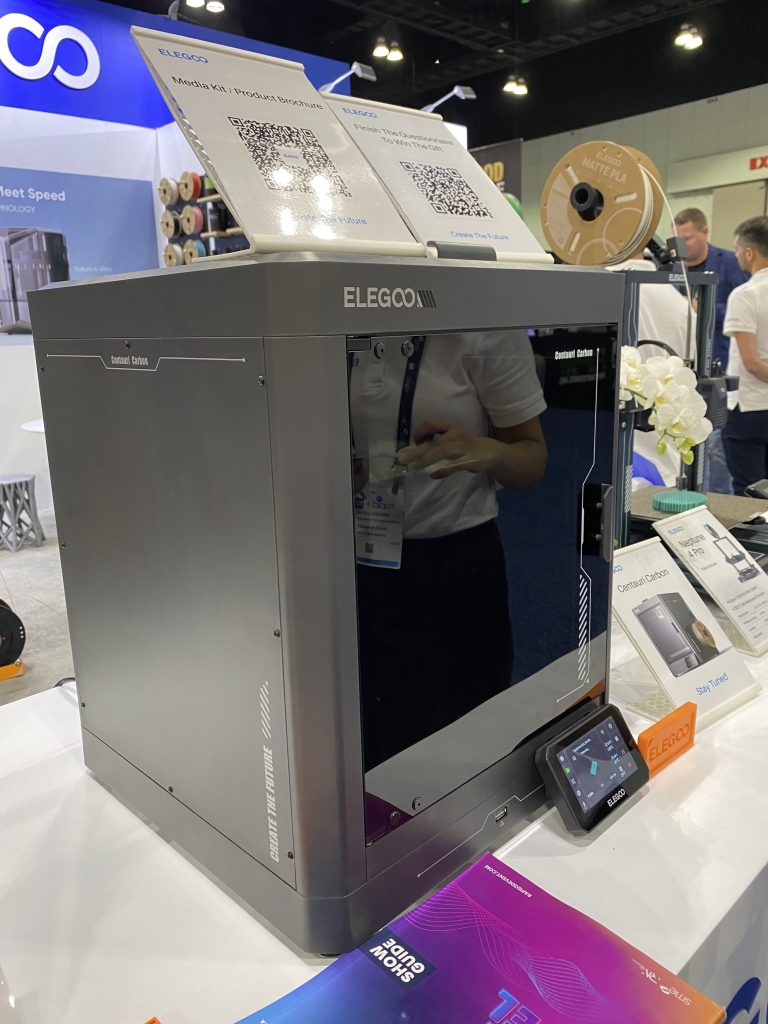

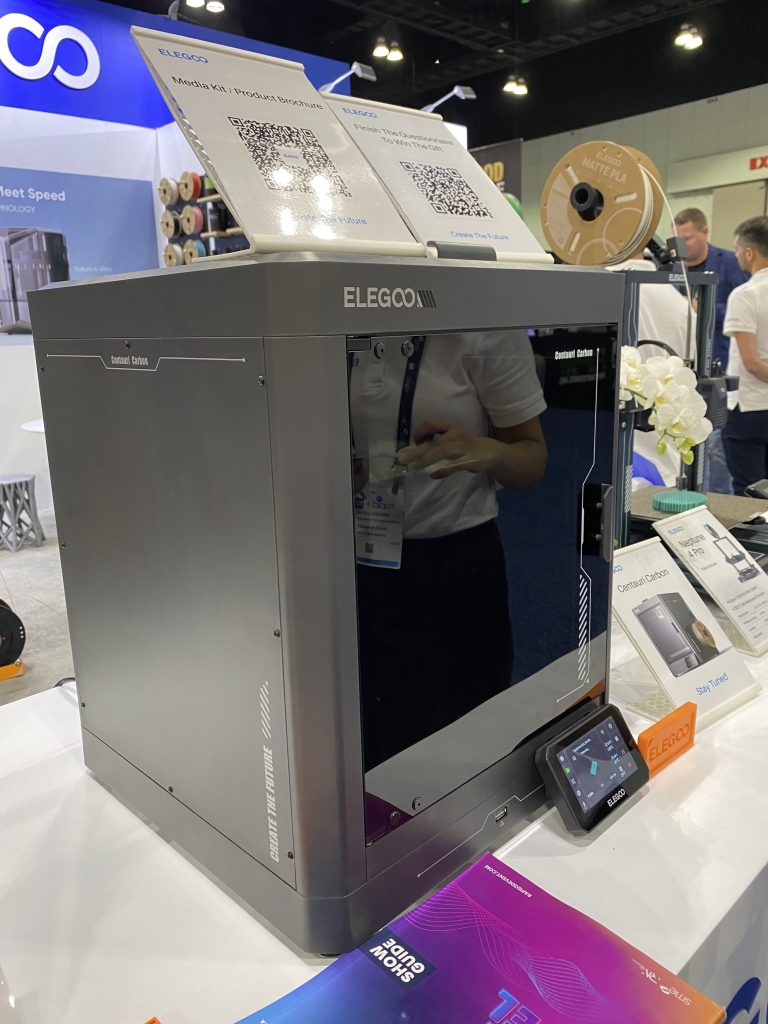

On the consumer side, Elegoo has a couple of exciting announcements. Firstly, the Shenzhen-based company has launched its new Mars 5 Series, which includes the Mars 5 and Mars 5 Ultra resin 3D printers. These new systems are available for pre-orders as of 10:00 am today.

The company has also unveiled a new FDM 3D printer which it calls “game-changing”. I am told that it is distinct from the company’s previous FDM systems, with a view to “revolutionizing” the consumer-grade market. Could this challenge the current dominance of Bambu Lab?

Showcasing 3D printing software

Towards the center of the hall, visitors will find New York-based Engineering software developer nTop (formerly nTopology). The company has today announced the launch of nTop 5, the next generation of its flagship 3D printing design software.

Notably, this new update includes integration with five new partners – Materialise, Autodesk, cloudfluid, Hexagon, and Intact Solutions. These companies have now all built nTop interoperability into their respective software offerings. CEO Bradley Rothenberg calls this new platform a “leap forward in implicit modeling technology.”

Next door, at booth #1547, visitors will not want to miss nTop and Cobra Golf’s Dryvebox. Here, Cobra is offering the chance to get hands-on with its new range of LIMIT3D 3D printed golf irons.

The company claims that these 3D printed clubs combine improved golfing performance with the look and feel of a professional iron. This is enabled by an internal lattice structure designed using nTop’s engineering software.

Nano Dimension is unveiling its Flight Hub software at RAPID + TCT 2024. The new platform is a comprehensive solution for designing electronics that incorporate 3D printed components. This allows users to create and refine components according to unique specifications.

Belgian-based Materialise is a big name in the world of 3D printing software. The company has announced a new update to Magics, its data and build preparation software. The upgrade is focused on ensuring first-time right 3D printing, introducing optimizations for polymer and metal users. The ability to handle complex data with beam lattices allows for enhanced designs and reduced weight of parts.

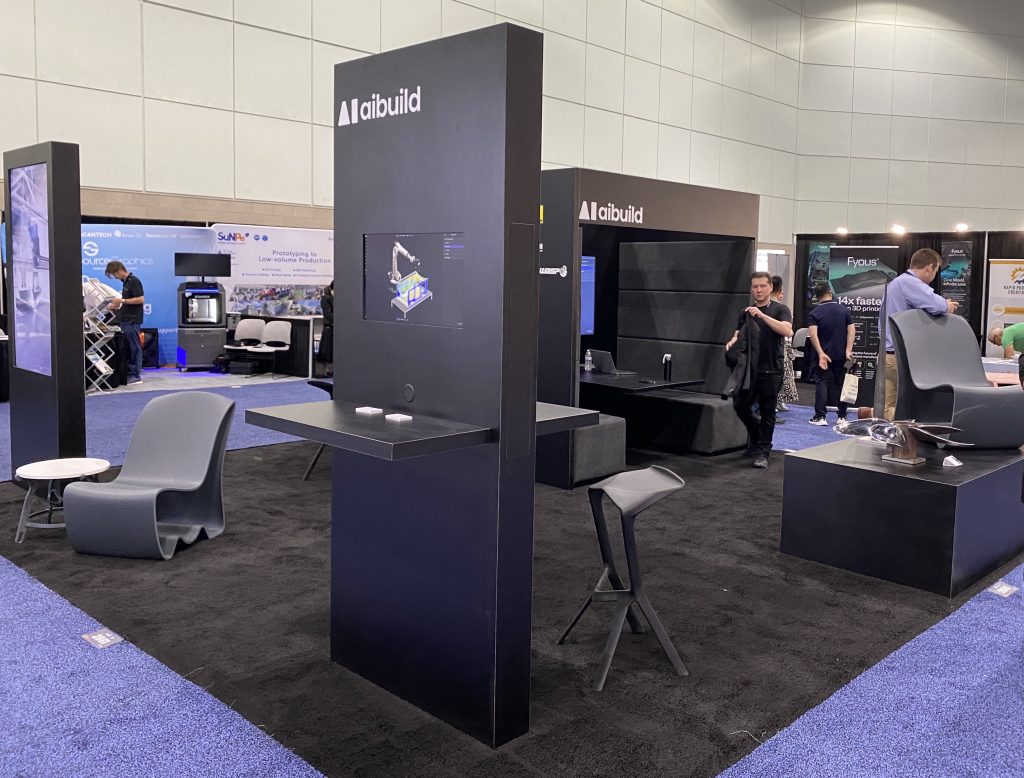

This is London-based 3D printing software developer AI Build’s first time at RAPID + TCT, which sees the unveiling of Aibuild 2.0.

The latest version of the company’s artificial intelligence (AI) powered tool-path generation software, Aibuild 2.0 sees the addition of several new features. These include a new built-in AI assistant (Talk to AI), increased automation, ISO 27001-certified cloud infrastructure, and a brand new user interface for increased accessibility.

Vibration compensation software developer Ulendo is launching its new Calibration-as-a-Service (CaaS) cloud-based solution. The company’s software speeds up extrusion 3D printers by measuring and counteracting vibrations. Ulendo CEO Brenda Jones claims “you can double the throughput of 3D printers with our software.”

The new CaaS offering is advertised as a “first of its kind” platform that enables 3D print farms and industrial manufacturers to automatically calibrate FDM 3D systems within seconds to improve productivity.

New post-processing equipment, 3D scanners and materials

VAC-U-MAX and GEMCO are launching AM-MPRR, their new jointly-developed metal powder recovery and reconditioning unit, at this year’s show.

Designed to support laser powder bed fusion (LPBF) and binder jet 3D printers, AM-MPRR supports the whole life cycle of metal powder. It is advertised as improving the productivity of metal 3D printing, with an ability to extract and reclaim powder in 85% less time than other systems.

Fellow metal post-processing specialists Addiblast is introducing the new MARS04, a de-powdering station for large and heavy metal parts weighing up to 900 kg.

With a build plate volume of 600 x 600 x 1000 mm, it features 2-axis rotation for 360-degree access to complex parts. The rotating table can be customized to meet specific build-plate sizes, with the integration of programmable blow-off nozzles, pneumatic knockers, and electro-vibrators also possible.

Swedish software developer Hexagon is showcasing the MARVELSCAN, its first handheld 3D scanner. Launched last month, the MARVELSCAN is designed to increase accessibility to high-quality metrology.

MARVELSCAN can reportedly decrease inspection time by as much as 50% by providing quality part data. Its built-in photogrammetry enables targetless scanning, making it well-suited for large parts and repetitive scanning applications.

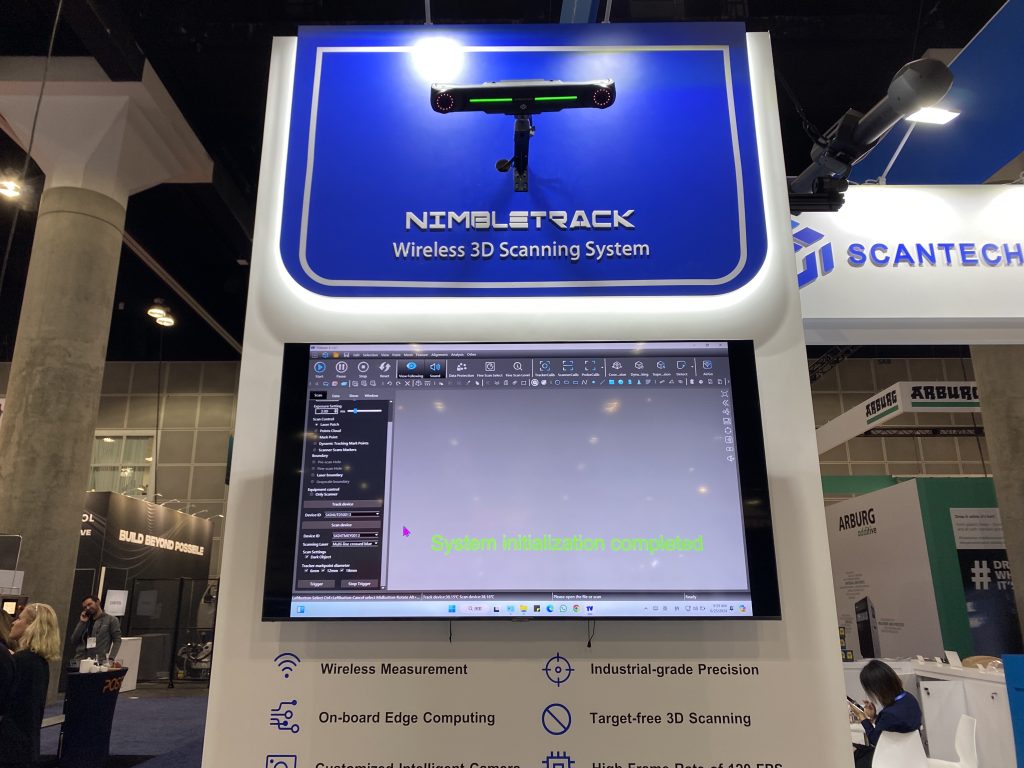

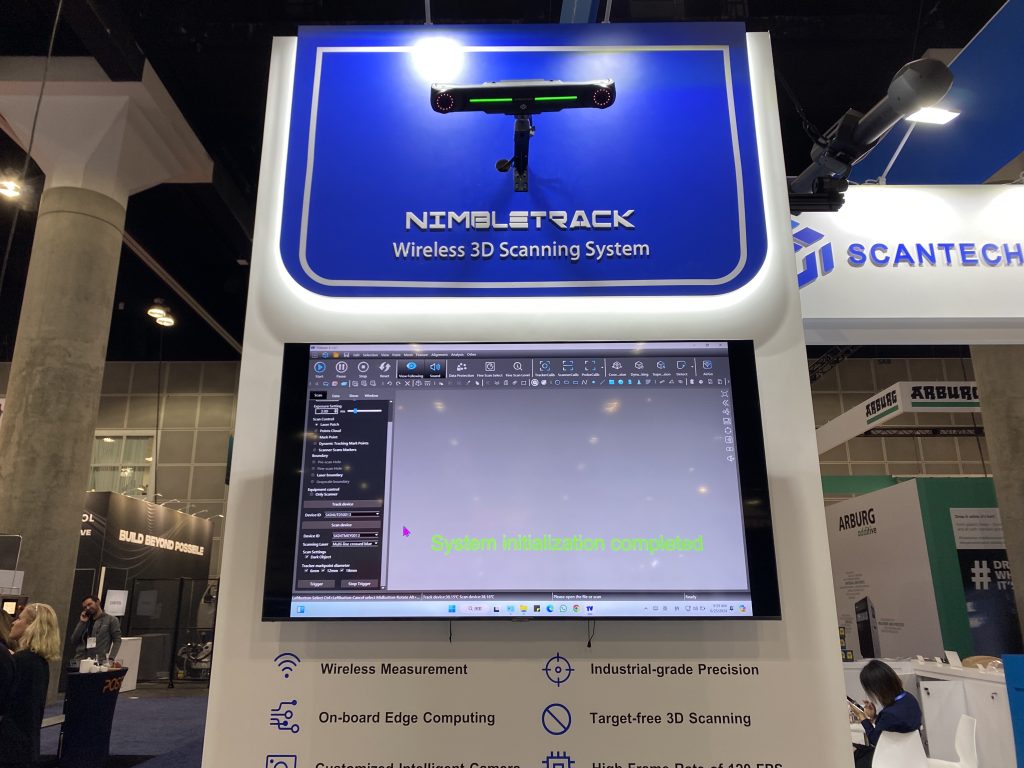

Located at resin 3D printer manufacturer UnionTech’s booth is Scantech, a developer of professional metrology-grade 3D scanners. RAPID + TCT 2024 sees the company demonstrate its newest offering – the Scantech NimbleTrack.

The 3D scanner targets engineers wanting to measure and analyze small-to-medium-sized parts in industrial settings. It can achieve an accuracy of up to 0.025 mm, and a maximum volumetric accuracy of 0.064 mm.

Visitors seeking new material announcements should call at booth #2317 to see Israeli 3D printer manufacturer XJet’s new 17-4PH stainless steel. The company’s new material reportedly offers high hardness and tensile strength.

It seeks to expand industrial applications across medical devices, aerospace, defense, oil and gas, and high-precision tooling sectors. A new soluble support material has also been added, something with xJet claims will minimize downtime for rapid production.

Lastly, it is worth visiting booth #1613 where Lithoz is launching its new Ceramic 3D Factory to the 3D printing market. This is a distributed manufacturing approach for industrial-scale production, uniting the company’s ceramic 3D printing technology with service bureaus around the world. The company claims this will enable serial production across semiconductor, aerospace, and medical technology applications.

Supporting the Ceramic 3D Factory is the company’s new CeraControl software, which is also being introduced at RAPID + TCT 2024. This platform can control 100 globally interconnected CeraFab S65 3D printers.

Register now for AMAA 2024 to hear insights from industry experts on additive manufacturing in aerospace, space, and defense.

Want to help select the winners of the 2024 3D Printing Industry Awards? Join the Expert Committee today.

What does the future of 3D printing hold?

What near-term 3D printing trends have been highlighted by industry experts?

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news.

You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

:quality(70)/cloudfront-us-east-1.images.arcpublishing.com/archetype/SV3STWAEWJH5HBP4W7NMXDOAMI.jpg?w=428&resize=428,400)