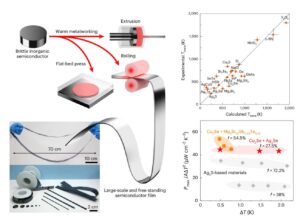

Diagram of warm-metalworking methods: rolling, extrusion, and flatbed pressing. Silver selenide (Ag₂Se) films produced at meter scale using warm rolling. Originally published in Gao, Z., Yang, S., Ma, Y. et al. Warm metalworking for plastic manufacturing in brittle semiconductors. Nat. Mater. (2025).

A recent paper published in Nature Materials notes that warm rolling, the same core process that turns aluminum ingots into beverage-can stock, can strengthen silver and copper chalcogenides. It notes, for instance, that “narrow-gap semiconductor Ag2Se can be plastically manufactured by warm metalworking.” Yield and tensile strengths climb significantly in Ag₂Se, Cu₂Se, AgCuSe and AgCuS when the compounds are rolled in their plastic temperature windows. Yet the improved mechanical profile comes with almost no penalty to electronic output. Room-temperature electrical power factors of warm-rolled Ag₂Se, Mg₃Bi₁.₅Sb₀.₄₉Te₀.₀₁ and Cu₂Se films stay within 10% of their bulk counterparts.”

Classic metallurgy teaches that strengthening often lowers carrier mobility by generating electron-scattering defects. Yet, this new warm rolling technique appears to largely overcome this common trade-off. Electrons move through these specially prepared materials with relative ease, with some achieving carrier mobilities up to four times that of silicon (and, as the paper notes, it is “~1–3 orders of magnitude higher than that of most two-dimensional materials”). Additionally, these high-performing crystals can now be shaped into long, thin ribbons.

A 90-centimeter ribbon

The poster child for the new approach is silver selenide. The researchers at Shanghai Institute of Ceramics of the Chinese Academy of Sciences and Shanghai Jiao Tong University began with a small, polycrystalline Ag₂Se slab, warmed it to roughly 420 K, and sent it through a rolling mill. Multiple passes transformed the nugget into a 90-centimeter strip, roughly 3,000 percent elongation, without cracking. In conventional thermoelectric ceramics, which often chip under minor handling.

That success rests on basic thermodynamics. Ag₂Se undergoes a brittle-to-ductile transition at 363 ± 20 K, a sweet spot high enough to activate dislocation motion yet low enough to retain the desired orthorhombic phase. Rolling above that threshold lets grains slide and rotate instead of fracture. Warm compression studies reveal dense networks of shear bands decorated by twisted, rotated and distorted lattice segments. Those defects serve as local soft zones that blunt cracks and, counterintuitively, toughen the material.

Silver selenide is not an outlier. Room-temperature-brittle Cu₂Se, Bi₉₀Sb₁₀ and other alloys also exhibit high plasticity when deformed below about 200 °C. The high temperature needed for plastic flow is still well below the melting points of the compounds, so conventional lab hot plates or even industrial ovens provide adequate heating. That accessibility fosters visions of roll-to-roll production lines rather than one-pellet-at-a-time hot-presses.

Industrial echoes

The convergence of high strength, big strain tolerance and robust electronic output will sound familiar to metallurgists who once shepherded aluminum from lab curiosity to everyday commodity. Warm rolling offers a similar bridge for inorganic semiconductors. Because the temperature windows sit in the hundreds, not thousands, of kelvins, existing aluminum or copper lines could, in principle, be retooled with only modest modifications, perhaps watt heaters in place of kilowatt furnaces.

Scale-up economics still matter. Silver, selenium and tellurium are not as abundant as iron or carbon, but thermoelectric modules require only thin strips: a 90-centimeter ribbon a few microns thick carries less than a gram of material. High recovery rates via recycling could further soften raw-material constraints.

Still, warm metalworking is no cure-all. Long-term stability under cyclic thermal loads, resistance to oxidation, and interface reliability in full modules remain open questions. Some of those issues may yield to the same defect engineering that unlocked ductility. Others may require barrier layers or novel encapsulation strategies, which the rolling process could deliver locally through clad or laminated architectures.

Looking ahead

The package deal of improved mechanical properties, maintained electronic/thermoelectric properties, and demonstrated potential in actual devices could push thermoelectrics past a commercial tipping point. Flexible ribbons sidestep mechanical fragility, unlock continuous production and conform to curved surfaces where temperature differences thrive. Add in predictive design tools that nail transition temperatures within about 30 K, and the odds of rapidly expanding the materials palette look good.

The next generation of waste-heat harvesters may well arise not from a furnace but from a rolling mill, one that has learned a few semiconductor tricks along the way.