SK hynix will introduce an artificial intelligence (AI) solution to its etching process that creates semiconductor circuit patterns.

SK hynix announced on Aug. 13 that its subsidiary Gauss Labs has released version 2.0 of its AI-based virtual metrology solution, Panoptes VM. Gauss Labs specializes in industrial AI.

Panoptes VM is a virtual metrology AI solution that utilizes data collected from sensors on equipment to predict the outcomes of manufacturing processes. It can predict the process outcomes of any product without need for physical full-scale measurement, dramatically reducing time and resources.

Gauss Labs, an industrial AI company which received investment from SK hynix, released Panoptes VM 1.0 in November 2022. In December of the same year, SK hynix introduced it to its mass production fab, applying it to a thin film deposition process and improving process variance by about 29 percent and increasing yields.

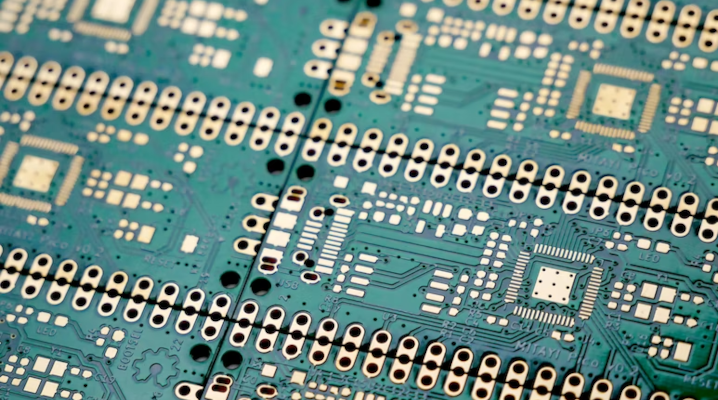

SK hynix plans to extend this improved solution to its etching process. Etching is the process of creating semiconductor circuit patterns by selectively removing unnecessary parts of a wafer using a liquid or gas corrosion solution.

To this end, Gauss Labs has added a multi-step modeling feature to the solution. This feature enables modeling by using both data from the processes to be predicted and the processes that were already done, which can be used to boost virtual metrology accuracy in the etching processes that were highly influenced by previous processes.

Gauss Labs engineers explained that they have added the “integrated modeling of similar processes” function which minimizes problems caused by a lack of data by integrating data from similar processes and using it for virtual metrology, and stressed the “automatic algorithm selection” function which automatically selects the best prediction algorithms according to data characteristics to enhance virtual metrology quality and user convenience at the same time.