What’s the story

Chinese scientists have developed an ultra-thin semiconductor material, a significant step toward creating faster and more energy-efficient processors.

The research team, led by Liu Kaihui of Peking University, Liu Can of Renmin University, and Zhang Guangyu from the Institute of Physics at the Chinese Academy of Sciences, has created a semiconductor material that measures just 0.7 nanometres in thickness.

Their findings were published in the peer-reviewed journal Science.

Technological advancement

Overcoming barriers in microchip miniaturization

The researchers’ work addresses a significant obstacle in reducing the size of traditional silicon-based chips.

As these devices become smaller, silicon chips encounter physical limitations that impact their performance.

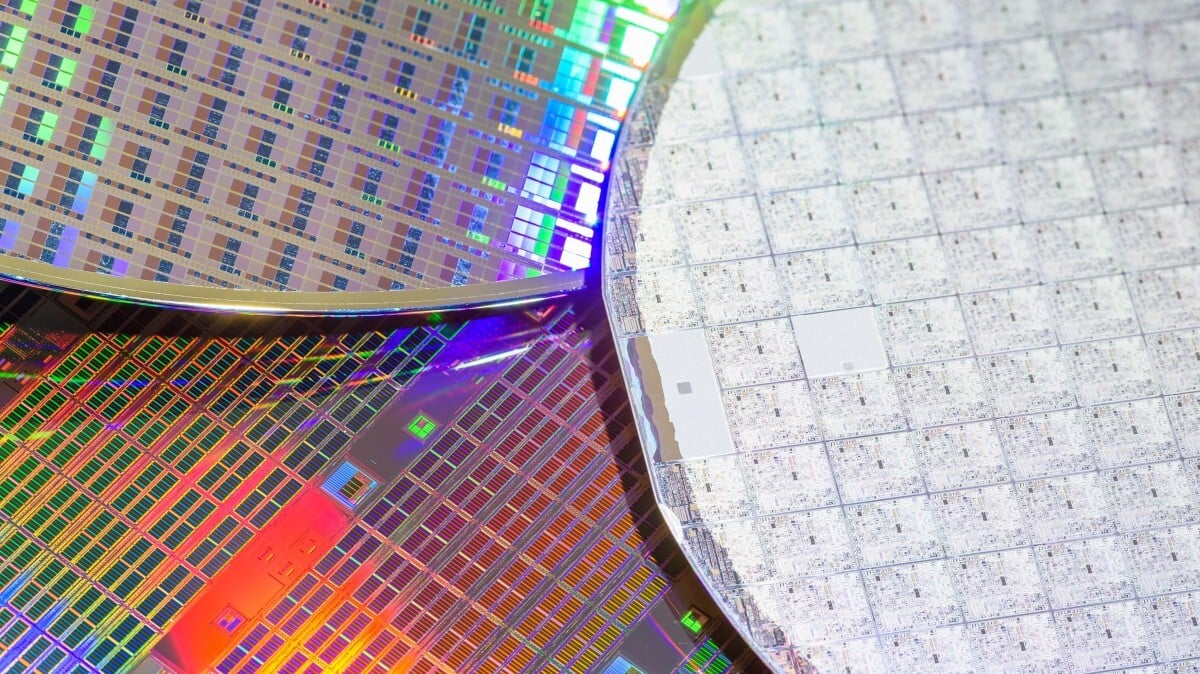

The team explored 2D transition-metal dichalcogenides (TMDs) as an alternative to silicon, which are only 0.7 nanometres thick compared to silicon’s typical 5-10 nanometres.

TMDs consume less power and have superior electron transport properties, making them ideal for ultra-scaled-down transistors in next-generation electronic and photonic chips.

New technique for high-quality 2D crystal production

Despite potential, producing TMDs has been a challenge due to uncontrollable atomic arrangements in crystal growth, and impurities and defects accumulation.

The team developed a new technique that allows them to quickly make high-quality 2D crystals in seven formulations.

This method involves arranging the first layer of atoms on a substrate as if following the traditional process, with subsequent atoms added between the substrate and the first crystal layer.

This pushes them upward like bamboo shoots to form new layers.

“Grow at Interface” method improves structural controllability

The “grow at interface” method ensures each crystal layer’s structure is determined by the underlying substrate, effectively preventing defect accumulation and improving structural controllability.

According to a statement from Peking University, this technique achieved a crystal layer formation rate of 50 layers per minute, with a maximum of 15,000 layers.

The researchers’ high-quality 2D crystals included molybdenum disulfide, tungsten disulfide, molybdenum diselenide, tungsten diselenide, niobium disulfide, niobium diselenide and molybdenum sulfoselenide.

2D crystals meet international standards

The materials met global standards for integrated circuit materials, including the International Roadmap for Devices and Systems’ electron mobility target, and frequency conversion capabilities.

Kaihui claimed these 2D crystals, when utilized as materials for transistors in integrated circuits, can significantly enhance chip integration.

He added that on a processor the size of a fingernail, the density of transistors can be substantially increased, thus boosting computing power.